Regardless that a final testing is not possible occasionally, a screening with the products parameter, on the other hand, may well previously be probable within an intermediate phase.

The techniques documented at this time will likely be integrated within “prepared grasp manufacturing and Handle records”.

When dealing with info — whether you’re collecting, examining or planning it for a knowledge-dealing with algorithm (like equipment Finding out algorithms) — you 1st should validate the different qualities of the data.

For the duration of this stage, the process design is confirmed as being capable of reproducible industrial manufacturing.

Each pharmaceutical manufacturer has to adjust to the necessities of present-day Good Manufacturing Practices (cGMP). To verify that quality standards are being achieved, there should be a systematic strategy by which data is gathered and studied to substantiate that processes work as meant. This systematic tactic is termed Validation.

This document will have to include facts of validation to become accomplished, and the timeframes for the scientific tests to get carried out. There needs to be clear statements with regards to that's to blame for Each individual Portion of the validation method.

Generally, as a result of have on and tear, with time, there may be a drift from normal running conditions. This can make it critical for brands to be certain they agenda a periodic revalidation of their programs, equipments, facilities, and processes to verify which they continue to carry out as anticipated to satisfy the prescribed top quality prerequisites.

We’ll have them wear the website aprons as well as hair nets that they’ll should once we start out selling our cakes.

In this sense, validation things to do will center on the most critical facets of processes, and these are definitely arrived at through a chance assessment technique.

The FDA outlines that pursuing a published protocol, authorized by all proper departments, is important to guide the manufacturing of PPQ batches.

If we combine equally definitions, it will become crystal clear that a process validation get more info presents a confirmation of a process bringing about the supposed process final results by goal evidence

If there is an important adjust within the production process along with the influence with the adjustments, e.g., leak check unsuccessful because of sealing complications in blister.

According to linked possibility and impact Examination the extent of PV shall choose which may well include the whole process that is definitely impacted.

Process validation is just expected if process outcomes can not be verified. These validation functions should comprise:

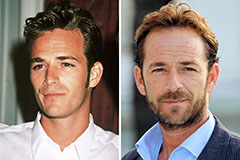

Luke Perry Then & Now!

Luke Perry Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now!